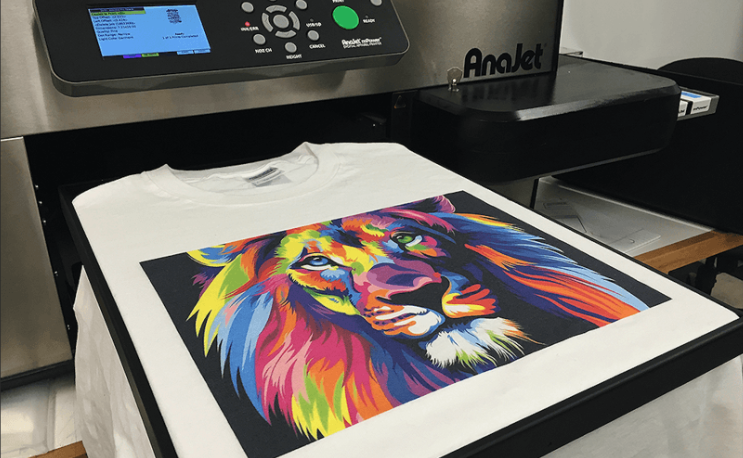

DTG printing is a technique for printing directly onto clothing – primarily cotton T-shirts and sweatshirts – using a special inkjet printer. A DTG printer works similarly to a home printer, but uses fabric as the substrate instead of paper.

What makes DTG printing unique?

- direct-to-fabric printing – ink penetrates the fabric structure

- eco-friendly

- ideal for multi-color graphics – ideal for printing photos, tonal transitions, and shaded element

- no need to prepare a matrix – can print from just one piece

- soft to the touch – the print is not “thick” like with foil or screen printing

Advantages of DTG printing

- excellent quality, high resolution

- personalization possible – printing single pieces

- eco-friendly water-based inks

- no color restrictions

Disadvantages of DTG printing

- works best on 100% cotton

- less durable than screen printing when washed frequently

- less cost-effective for large quantities

COMPARISON: DTG VS. SCREEN PRINTING VS. DTF

PRINTING TECHNIQUE

DTG

(DIRECT TO GARMENT)

(DIRECT TO GARMENT)

SILKPRINTING

DTF

(DIRECT TO FILM)

(DIRECT TO FILM)

minimum quantiy

1 piece

minimum 100 pieces

1 piece

unit cost

higher for smaller quantities

lower for higher quantities

medium

quality of the colours

Very good, photographic

very good, vivid colours

very good, high sharpness

print durability

average- good

very durable (washing resistant)

good- very good

trinting time

fast

longer ( preparation of the screens)

fast ( after preparation of the film)