DTF is a modern, versatile, ingenious, and effective method for creating multi-color prints, even at low production runs, starting from just one piece! Unlike traditional methods such as screen printing or flex printing, DTF printing allows for the quick creation of multi-color, detailed graphics, even with single pieces.

You can also order DTF heat transfers from us for self-heating.

The DTF printing technique involves printing the selected graphic on a special PET film designed for DTF printing. The printed design on the film is then coated with a special powder that acts as an adhesive, primer, and activator.

The prepared film is then heat-sealed onto the fabric, and the print is cured. DTF printing is characterized by low preparation costs.

We heat-seale the prints onto finished products and onto cutouts before sewing.

DTF prints are characterized by:

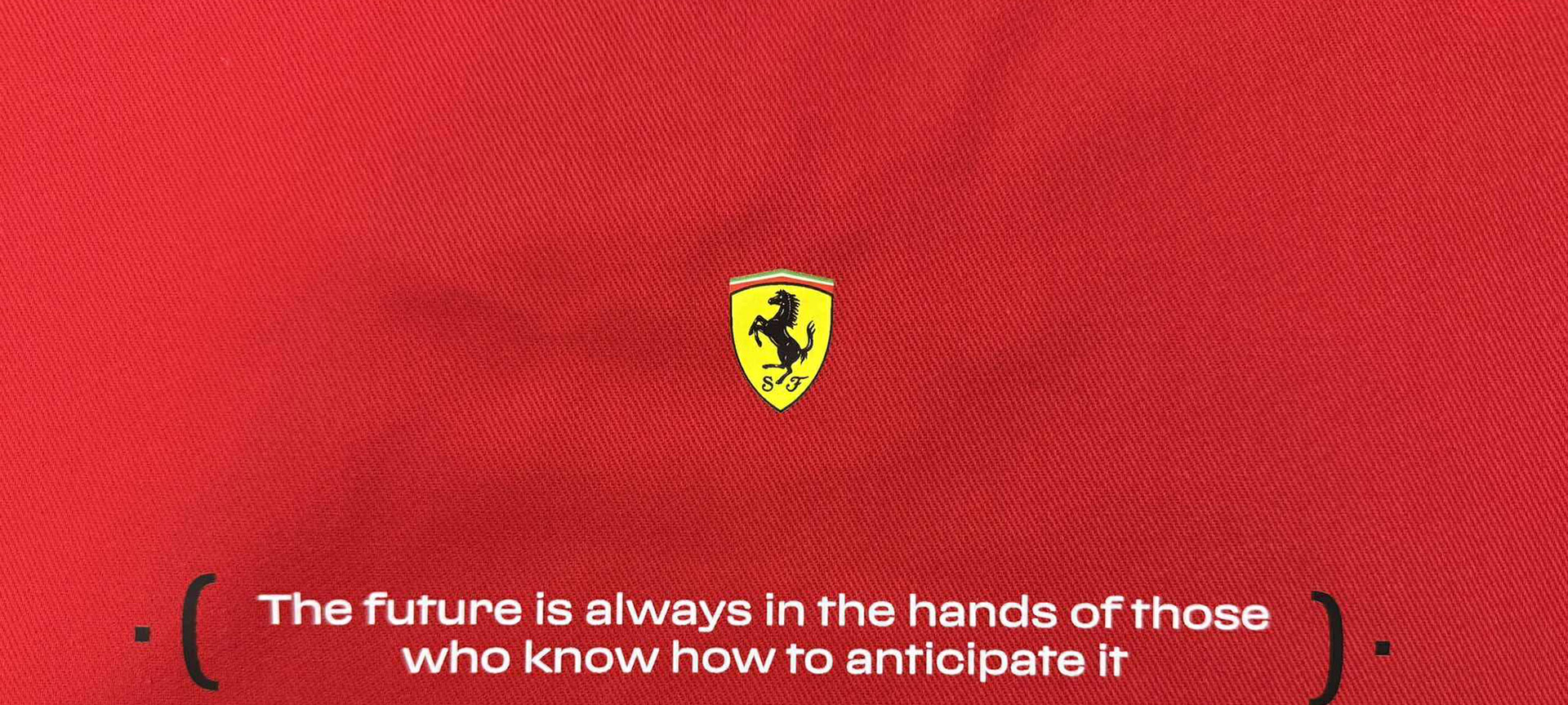

- clear, vivid, saturated colors

- high quality

- durability (significantly more durable than DTG prints)

- flexibility (more flexible than DTG prints)

- smoothness – very little perceptibility (smoother than prints created using other printing techniques)

- DTF prints do not affect the quality or structure of the material

- greater stretchability than DTG prints

- versatility – prints can be heat-sealed onto cotton, polyester, and other blends

- no color restrictions – a full range of colors, perfect whites and deep blacks

- no minimum order quantity – order as much as you need!

DTF prints can be printed on film in advance and heat-sealed later if needed.

We print DTF prints on our products and provide transfers for our customers to heat-seale themselves.

How to order a DTF print?

- Prepare your graphic – PNG format (transparent background), 300 dpi.

- Send the file – by email to biuro@cotton-bag.pl

- Choose a fulfillment option – print on foil or ready-made product.

- Your order will be ready in as little as 24 hours!

Colors – CMYK or RGB?

DTF printing supports both RGB and CMYK modes. However, we recommend sending your graphics in RGB, as DTF printing technology preserves color intensity, especially with bright colors. If your design is prepared in CMYK, it will also print correctly

- Recommended: RGB for vibrant colors

- Acceptable: CMYK

Design size – how to set it?

Prepare the design exactly the size it will be printed. Avoid scaling later, as this may affect quality. For example, if the print is to be 30×20 cm, prepare the file in that size.

COMPARISON: DTG VS. SCREEN PRINTING VS. DTF

(DIRECT TO GARMENT)

(DIRECT TO FILM)